Hand Made?

One of the most important words in our tagline is ‘hand-made‘ but what does it actually mean and what picture does it conjure in your head? We recently did a blog on the workshops of our craftsmen to give you an idea of where our broad range of woodwork is made and that is, mostly, in little one man workshops all over the country. Now let’s take a closer look at the hands on process by which a piece of wood is turned into a piece of woodcraft. Woodworkers of today naturally use power tools to free them from hours of hand sawing, chiselling and hand sanding but the thing is, those tools still have to be hand guided and operated well to produce a good article.

Hard to Handle an Arbortech

Our beautiful natural edge burl bowls are made using an arbortech, in essence a mini angle grinder. It requires a deal of skill and strength to guide it through the uneven matrix of knots and buds that make up a Eucalypt burl. The arbortech can skitter out of control so easily that producing a controlled curve takes many hours, even years of experience.

Bandsaws, Sanders and Broken Fingernails

Our bandsaw jewellery and trinket boxes require several processes in their making. Here you can see John Tudehope go through the various stages beginning with using the bandsaw, rough sanding, gluing and fine sanding. Not shown is John applying several coats of tung oil finish to his pretty trinket boxes. Alan Williams makes his band saw boxes the same way but hand carves the drawer fronts to give his compartment boxes their finger pulls. Michael Cox uses a bandsaw to take slices from a large, shaped piece of hardwood to make his range of Red Hardwood kitchen utensils which are then sanded, edged and dipped in beeswax – all by hand.

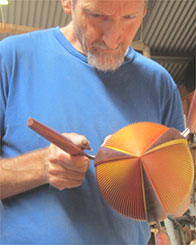

Masters of the Lathe

Turners who use a lathe are very skilled artisans who need a keen eye and great manual dexterity. All the lathe does is spin the piece of wood while the turner holds his chisel against it. The turner applies varying pressure and angles to his chisel to produce the forms he wants. Here is Tony Hansen turning a Banksia pod for a hollow t-light candle, Trevor Short turning an Orb pepper mill and Dean Malcolm hand finishing a beautiful turned form for an exhibition of his wooden artworks. It should be mentioned here that keeping tools sharp and machines running well is vital so woodworkers are necessarily a handy bunch.

So, even with the convenience of modern power tools the artisans featured on these pages are still very much hands on craftsmen who can rightly label their products hand-made. I’m sure many of them wish they could put a piece of wood into a machine and have a finished product pop out at the other end – on those days when their fingers are sore from sanding and shoulders aching from the lathe but no, the only way to make these things is to do it by hand.